Products

Pellet gyártó gépsorok

We try to improve and to make fool-proof our machines and production lines meeting our experience and users needs too. of course, failures, part fractures, abrasions occur.

As we are the manufacturer of the whole production line we can ship spare parts with short delivery time.

Our services cater all aspects of pellet processing. we provide technical support for every problem occurs during the pellet processing from moving the raw material to the packaging the finished products.

Feel free to contact us.

- Hammer mill in different type and size,

- Raw material conditioner,

- Conveyors in different length that fit all the requirements,

- Belt conveyor and powered rolled conveyors,

- Raw material drag conveyor,

- Silo, raw material container ,

- Sifter, air-separator ,

- Rotary screener

- Bagging system extended with force feeders (cell, screw-type, belt, vibrating),

- Portioning extended with force feeders (cell, screw-type)

- Bag and cyclon dust collector with air lock

- Exhaust systems from single extraction system to industrial ventilation,

- Pellet mill; pellet production line from 0.2t/h to 5t/h

- Automatic controlling system with remote surveillance service in an adequate way which covers the mobile phone or internet line based remote surveillance.

- Pellet packing machine, packer into ‘big-bag’ sack, into 15 kg sack

- Pellet cooler system with sifter and puffer storage

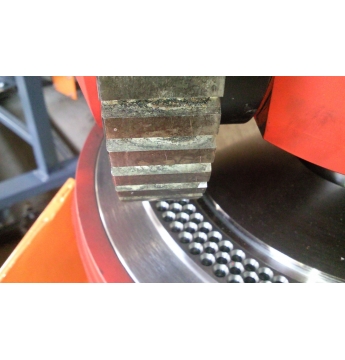

- We manufacture different pellet mill dies for different flat die pellet mills and different raw materials.

- Producing trundles, machine parts. machining, grinding.

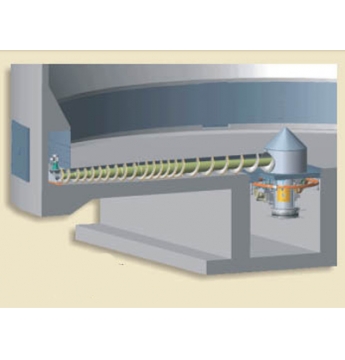

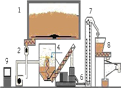

Our industrial pellet mills are suitable to create pellets from compacted sawdust or other wastes from sawmilling and other wood products, but also from sources such as whole-tree removal or tree tops and branches leftover, energy grass, and also from industrial waste and biomass.

Our industrial pellet mills are suitable to create pellets from compacted sawdust or other wastes from sawmilling and other wood products, but also from sources such as whole-tree removal or tree tops and branches leftover, energy grass, and also from industrial waste and biomass.  We manufacture different pellet mill dies for different flat die pellet mills.

We manufacture different pellet mill dies for different flat die pellet mills.  Our production line is suitable to produce pellet from 200kg/h up to 5 t/h. we provide you the definite series of flat die pellet mills. they are ideal machines that fit all the requirements. its adequate size, compact structure, easy operation make it welcome by customers all over the world.

Our production line is suitable to produce pellet from 200kg/h up to 5 t/h. we provide you the definite series of flat die pellet mills. they are ideal machines that fit all the requirements. its adequate size, compact structure, easy operation make it welcome by customers all over the world.